Innovative Trends in Steel Manufacture: Enhancing Toughness and Accuracy

In the world of steel construction, the quest of toughness and accuracy has brought about a wave of ingenious patterns that are improving the sector. From improvements in welding innovations to the combination of robotic automation in construction processes, the landscape of steel manufacturing is developing swiftly. High-strength alloy advancement, coupled with the utilization of 3D modeling and simulation software program, is pressing the boundaries of what is possible in terms of architectural integrity and precision. The growing focus on lasting practices in steel manufacturing is not just driving efficiency however also promoting a much more eco mindful approach to manufacture. These patterns are not simply forming the here and now however likewise laying the foundation for the future of steel fabrication, guaranteeing more improvements in toughness and precision.

Advanced Welding Technologies

In the realm of steel manufacture, the adoption of advanced welding technologies has substantially changed the market's method to attaining exceptional high quality and accuracy in structural welds. Advanced welding modern technologies, such as laser light beam welding and friction stir welding, have actually emerged as game-changers in the field. Laser beam of light welding employs a focused laser light beam to join metal elements with impressive precision and rate, making it excellent for intricate layouts and thin materials. On the various other hand, rubbing mix welding produces extremely solid bonds by mechanically intermixing the molecules of the products at the joint, removing the requirement for melting the metal. These innovations offer many benefits, consisting of minimized heat-affected areas, marginal distortion, and improved mechanical residential or commercial properties in the bonded joints. By leveraging these innovative welding methods, steel makers can elevate the sturdiness, toughness, and accuracy of their structural welds, meeting the progressively demanding needs of contemporary building projects.

Robotic Automation in Construction

Welcoming robotic automation has come to be a keystone of modern steel manufacture methods, simplifying processes and improving performance throughout the sector. Robotics are revolutionizing the method steel parts are produced, using unparalleled accuracy and rate while minimizing human mistake. These automated systems can deal with repetitive tasks with constant accuracy, bring about better final product.

One secret benefit of robotic automation in steel manufacture is the capacity to function all the time without exhaustion, significantly enhancing production result. This continuous operation minimizes downtime and accelerates project timelines, ultimately saving costs for manufacturers. In addition, robots can be configured to perform complex tasks that might be harmful or tough for human employees, enhancing safety and security in the workplace.

Moreover, robot automation enables seamless integration with various other electronic modern technologies, such as computer-aided style (CAD) software application and Internet of Points (IoT) systems (Alpha reo). This interconnected method enhances communication in between different stages of construction, maximizing workflows and making sure real-time tracking and control. As the steel fabrication sector continues to progress, robotic automation attracts attention as a transformative pressure driving effectiveness and precision in manufacturing processes

High-Strength Alloy Advancement

The improvement of high-strength alloy advancement in steel construction is reshaping the market's technique to boosting product sturdiness and efficiency. High-strength alloys are crafted to exhibit superior mechanical homes, such as increased tensile toughness, durability, and corrosion resistance contrasted to typical steel qualities. By incorporating these sophisticated alloys right into construction processes, makers can produce parts that withstand greater stress levels and severe settings, causing more reliable and sturdy end items.

One key advantage of high-strength alloy growth is the capacity to lower product density without endangering structural integrity. This not only causes lighter-weight components yet likewise adds to cost financial savings and enhanced performance in construction and setting up processes. The boosted strength-to-weight proportion of these alloys permits for the layout and building of structures with higher load-bearing capacities while decreasing overall weight.

3D Modeling and Simulation Software Application

Improvements in steel manufacture processes have actually been significantly pushed by the assimilation of cutting-edge 3D modeling and simulation software program tools. These devices enable makers to develop in-depth virtual versions of their tasks, allowing them to picture the final product with accuracy prior to any physical work begins.

Sustainable Practices in Steel Manufacturing

Including lasting practices into steel manufacturing processes is crucial for decreasing ecological effect and guaranteeing long-lasting resource accessibility. One key sustainable technique is the fostering of energy-efficient innovations to lower greenhouse gas discharges throughout the steel production procedure. This consists of making use of renewable resource resources, such as solar or wind power, to power steel plants and applying energy-efficient equipment to enhance energy usage.

An additional essential facet of lasting steel production is the liable sourcing of resources. This involves making sure that the iron ore and various other sources made use of in steelmaking are gotten from environmentally pleasant and moral sources. By promoting openness in the supply chain and sticking to rigorous ecological standards, steel producers can lessen the adverse influences of source extraction on neighborhood ecological communities websites and communities.

Verdict

In conclusion, the cutting-edge fads in steel construction such as sophisticated welding modern technologies, robot automation, high-strength alloy advancement, 3D modeling and simulation software, and lasting methods are boosting the toughness and accuracy of steel products. These innovations are transforming the useful site steel manufacture industry by improving efficiency, quality, and sustainability. It is clear that the future of steel construction depends on welcoming these innovative technologies to satisfy the demands of modern-day construction and manufacturing industries.

In the world of steel fabrication, the search of toughness and accuracy has actually led to a wave of cutting-edge fads that are reshaping the market.In the world of steel fabrication, the adoption of sophisticated welding technologies has actually significantly reinvented the sector's method to attaining superior quality and accuracy in structural welds. As the steel construction sector continues to progress, robot automation stands out as a transformative force driving performance and accuracy in manufacturing processes.

Moreover, reusing and recycling steel scrap and waste materials play a significant function in boosting the sustainability of steel manufacturing. metal fabrication this contact form melbourne.In final thought, the cutting-edge fads in steel manufacture such as advanced welding technologies, robot automation, high-strength alloy advancement, 3D modeling and simulation software, and sustainable methods are improving the toughness and accuracy of steel items

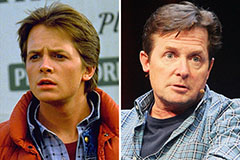

Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Sydney Simpson Then & Now!

Sydney Simpson Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!